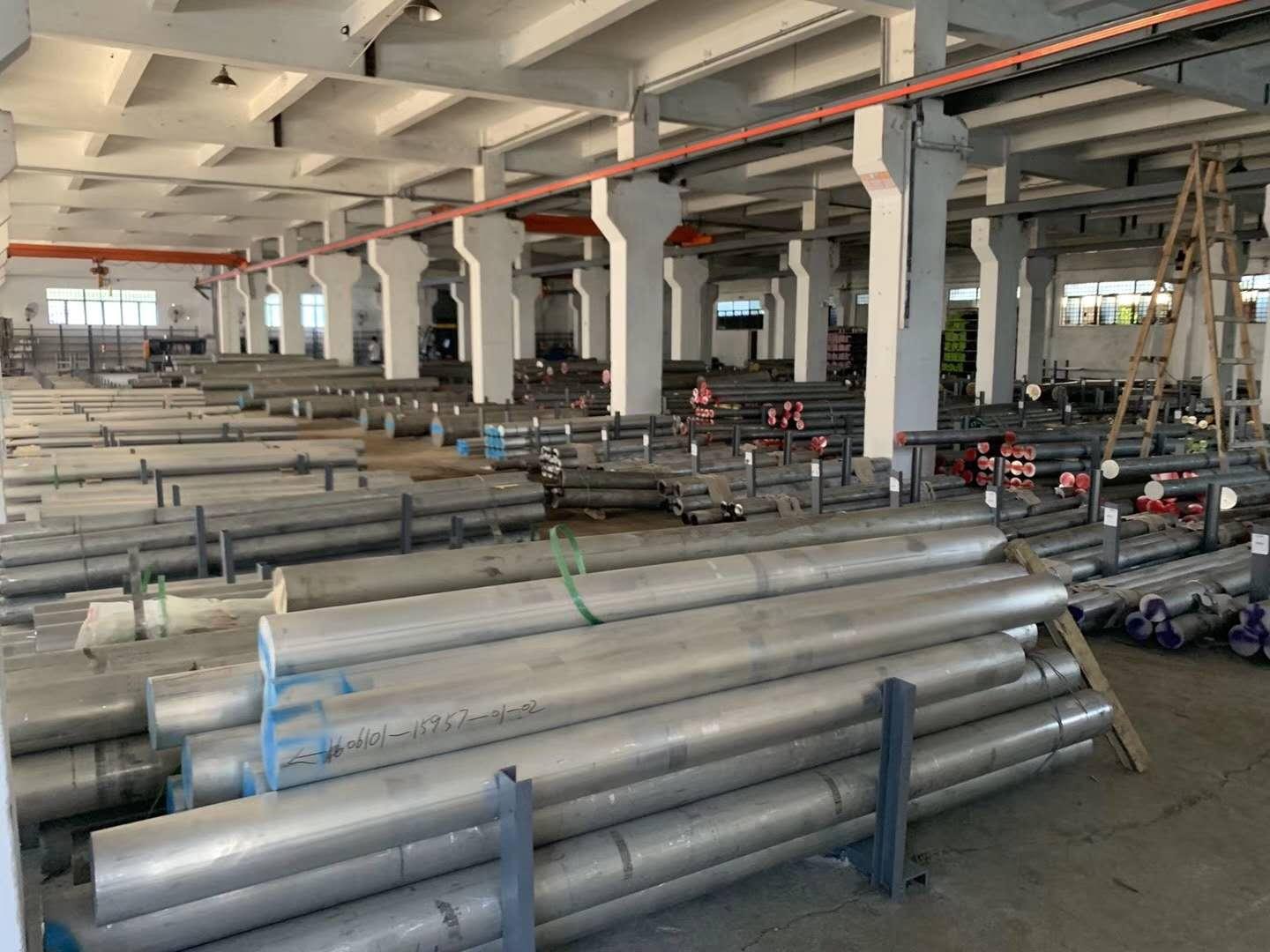

A2017 alloy aluminum aluminum rod aluminum

Al2017 is a typical duralumin of aluminum-copper-magnesium system materials. The alloy has reasonable composition proportion and good comprehensive performance. It is an aluminum alloy material with a large amount of duralumin. The aluminum alloy is easy to crack when welding, and can be welded or riveted by special technology. The aluminum alloy has the following characteristics:

High compressive strength,

Excellent yield strength,

Good heat resistance,

Excellent dimensional processing performance,

Good material toughness,

Excellent cutting performance.

Chemical composition:

Chemical composition of Al2017 aluminum alloy

Si0.5fe0.3cu4.0mn0.7mg0.6cr0.01zn0.01ti0.03zr0.05al allowance

Mechanical properties:

Mechanical properties of Al2017 aluminum alloy at room temperature are as follows:

Tensile strength 390Mpa,

Yield strength 245Mpa,

Fatigue strength 290Mpa,

Shear strength 105Mpa,

Elongation 22%,

Hardness is 100 hb

Physical performance:

Physical properties of Al2017 aluminum alloy plate at room temperature are as follows:

Elastic modulus: 73GPa,

Thermal expansion coefficient 23.5,

Thermal conductivity 167,

Melting point range 513-640,

Electrical conductivity 34,

Resistivity 0.052,

Density: 2.8g/cm3.

USES:

Due to its good comprehensive performance, Al2017 aluminum rod is a very large material used in 2 series of duralumin, mainly used as a structural material; Its main uses are as follows:

High precision machinery parts,

Materials and frames for aircraft skins,

Ship propeller elements,

Building structural parts,

Wainscoting and landing gear struts,

SMT, PC board solder carrier, etc.

High compressive strength,

Excellent yield strength,

Good heat resistance,

Excellent dimensional processing performance,

Good material toughness,

Excellent cutting performance.

Chemical composition:

Chemical composition of Al2017 aluminum alloy

Si0.5fe0.3cu4.0mn0.7mg0.6cr0.01zn0.01ti0.03zr0.05al allowance

Mechanical properties:

Mechanical properties of Al2017 aluminum alloy at room temperature are as follows:

Tensile strength 390Mpa,

Yield strength 245Mpa,

Fatigue strength 290Mpa,

Shear strength 105Mpa,

Elongation 22%,

Hardness is 100 hb

Physical performance:

Physical properties of Al2017 aluminum alloy plate at room temperature are as follows:

Elastic modulus: 73GPa,

Thermal expansion coefficient 23.5,

Thermal conductivity 167,

Melting point range 513-640,

Electrical conductivity 34,

Resistivity 0.052,

Density: 2.8g/cm3.

USES:

Due to its good comprehensive performance, Al2017 aluminum rod is a very large material used in 2 series of duralumin, mainly used as a structural material; Its main uses are as follows:

High precision machinery parts,

Materials and frames for aircraft skins,

Ship propeller elements,

Building structural parts,

Wainscoting and landing gear struts,

SMT, PC board solder carrier, etc.